The Interview | Michael Ambrose, National Highways Concrete Roads Programme

Reaping the benefits of re-thinking road concrete use

By Ty Byrd

A dearth of relevant up-to-date knowledge about one of construction’s principal structural materials threatened to hinder the biggest-ever programme to rebuild and revitalise England’s many concrete roads. The Concrete Roads Programme is now well underway with renewal of the A11 at Norwich (NCE, April 2023).

“Relatively little had been done around concrete development for 20 years and catch-up was urgently required,” declares National Highways Concrete Roads Centre of Excellence technical lead Michael Ambrose.

MICHAEL AMBROSE

MICHAEL AMBROSE

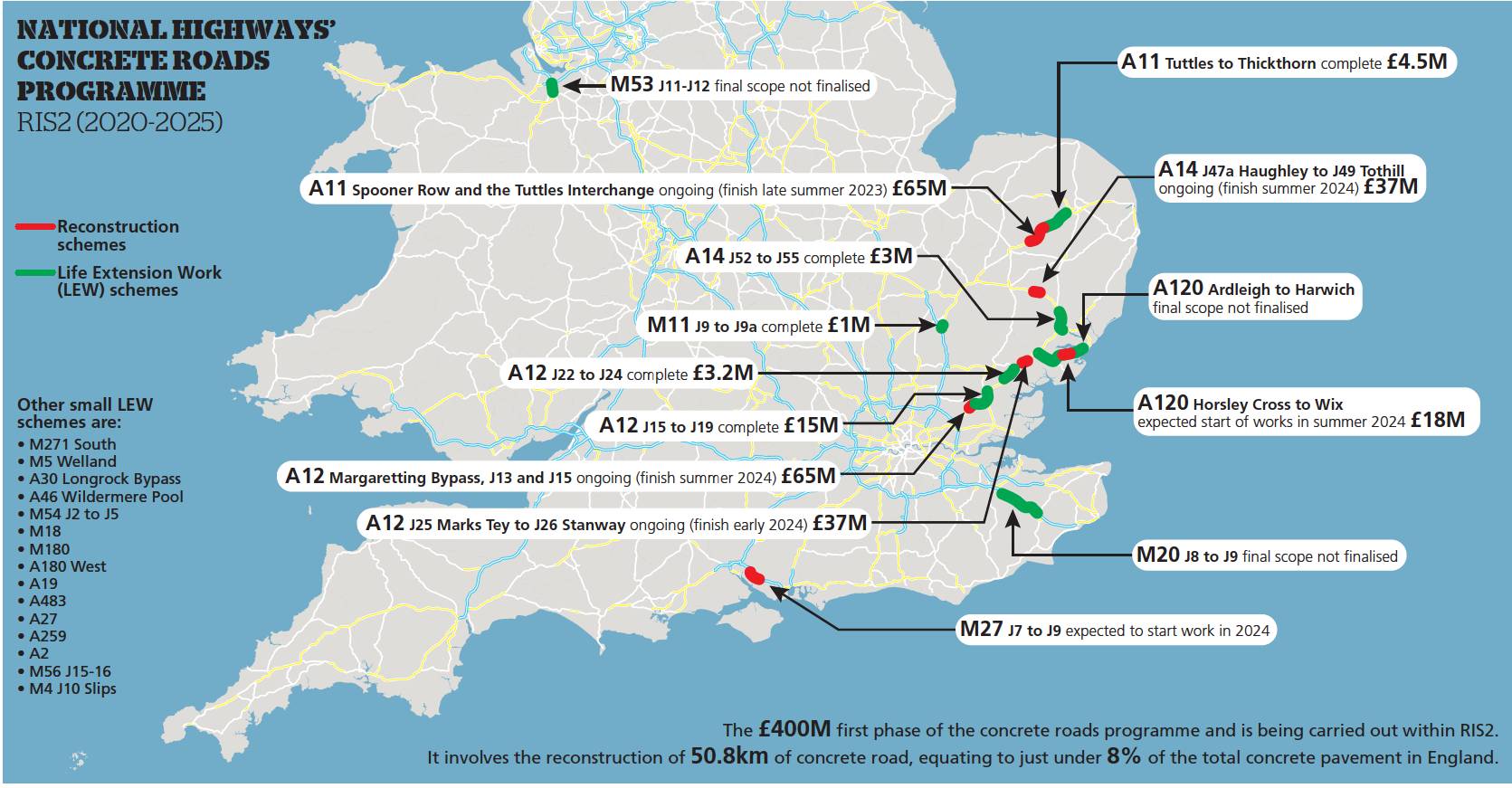

This became clear in 2019, ahead of Road Investment Strategy 2 (RIS2) – covering the period 2020 to 2025 – and the commencement of National Highways’ Concrete Roads Programme to reconstruct or extend the life of England’s 644km of concrete roads. Construction activity began in 2020, with Ambrose expecting the programme to be complete within RIS6 to RIS8, meaning a possible finish in 2060.

“Concrete technology needed to be transformed in respect of recycling and reuse, reduced CO2 2 footprint and more generally, via thinking out of the box,” Ambrose says.

There was also concern within National Highways that concrete was not being “promoted” sufficiently to young engineers and that old hands with practical roads-related experience of the material were retiring from the industry – meaning a potential skills shortage to come.

“So it was decided right away – in 2019 – to establish a concrete roads Centre of Excellence (CofEx),” Ambrose says, “which I head up.”

The centre was assigned terms of reference that include combining advances in concrete technology, safety and environmental practice to make better, longer-lasting roads; plus securing the interest of a new generation of engineers.

From the start, CofEx was conceived as a virtual entity, meaning it has no research and development (R&D) infrastructure of its own. The centre effectively serves as an agency which commissions what R&D needs to be done to suit its priorities.

“Concrete technology needed to be transformed in respect of recycling and reuse“I have just three colleagues in my team. We cooperate – inter alia – with the intelligent materials section of Cambridge University, helping steer the university’s digital roads programme,” Ambrose says.

“We also work with Derby and Northumberland universities; consultants such as Aecom, Mott MacDonald and Sweco and contractors like Costain.”

Recycling and reuse of concrete had to be an early priority as it was a big issue – not least in keeping the Concrete Roads Programme’s carbon footprint to a minimum and contributing to the circular economy.

“RIS2 was going to involve coping with 400,000m2 of recovered concrete – good Type 1 – most of it to be earmarked for use in reconstruction projects or handed over for other schemes.