The biggest issues of the month explored | Tunnels

Inside Track

Tunnels

Gerrards Cross collapse details finally released

Report into 2005 accident released after Freedom of Information battle

By Rob Hakimian

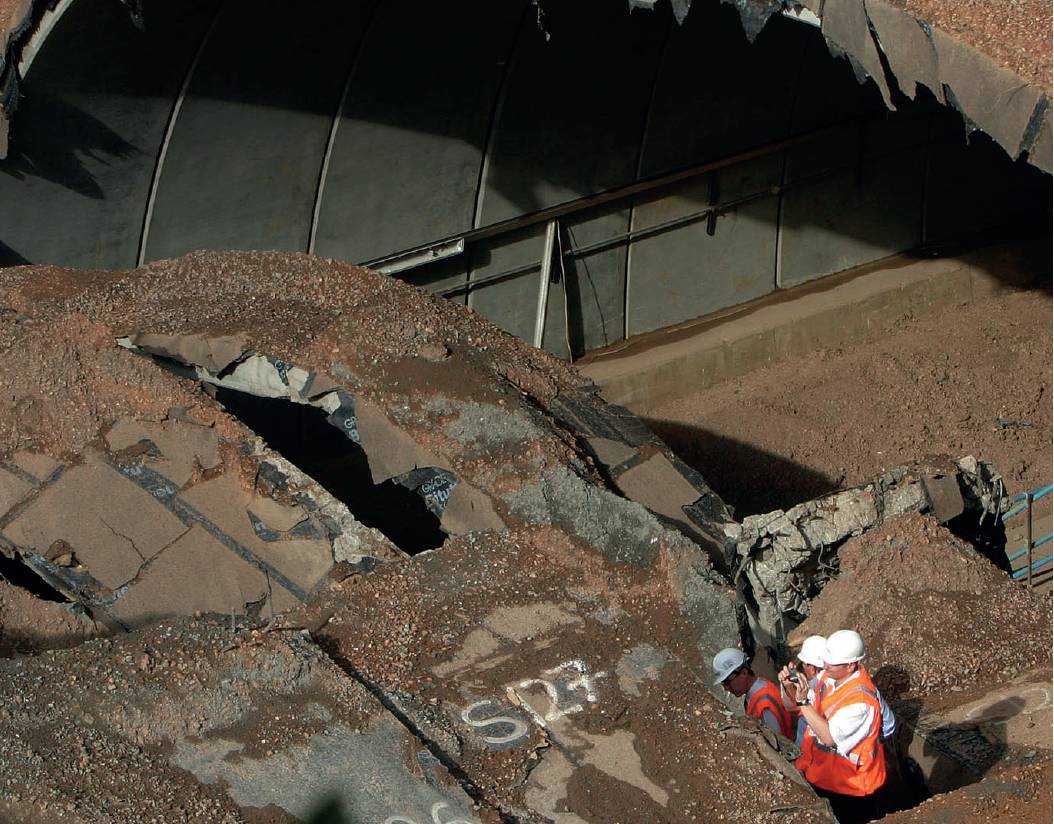

Events that led to the 2005 Gerrards Cross tunnel collapse during construction have emerged in a previously unpublished Health & Safety Executive (HSE) report.

The collapse occurred after precast concrete panels which were installed to form the railway tunnel failed as backfill was placed on them to create ground for a Tesco store.

The rail line was closed for seven weeks following the tunnel collapse in 2005

The rail line was closed for seven weeks following the tunnel collapse in 2005

An HSE investigation was launched following the incident but the report has only just been released following a battle with the Information Commission’s Office after the failure to publish was reported on railway engineer and writer Gareth Dennis’ Rail Natter podcast.

The HSE report describes how four contractors tendered for the project.

Jackson Civil Engineering won the contract but raised no concerns about the design at the tender stage and offered no alternative proposals. However, the report says that by submitting a design and build tender, it accepted responsibility for managing the design risks.

It was awarded the contract in April 2003, with its £25M bid coming in around £3M lower than the next offer. Consultant White Young Green (WYG) – now part of Tetra Tech – designed the tunnel, incorporating a specialist reinforced concrete arch design developed by Reco and using its Tech Span system.

This is an “arch” design consisting of three pins at the top securing two interlocking segmental precast steel reinforced concrete sections. A total of 343 precast sections were installed.

The HSE report says the tunnel was initially designed to house two railway tracks but that it was later decided to make it wide enough for four, potentially to accommodate freight. The report states “due to the floor level and height of the proposed store needing to remain, the designer kept the crown of the arch at the same level... the effect of maintaining the crown level while increasing the span was to create a much flatter arch. This had implications on the design”.

Piling work started in June 2003 and main work for the 324m long tunnel started in July 2004, with the railway remaining live the whole time.

The HSE report explains that when the erection of the sections was complete, backfilling could commence, but it points out that there was a risk that the arch structure’s stability could be affected by asymmetrical loading.

Despite the release of the report, some of the concluding pages were redacted so the full findings of the investigation have yet to be published. As a result it is still unclear whether the loading from Jackson’s backfilling caused asymmetrical loading. However, the report does point to the weight of the backfill as being a trigger for the failure.

Jackson was responsible for managing the backfilling operation and subcontracted Clark Construction for the job. The HSE report states: “It is not clear how the fill should progress in the method statement.”

It appears that the backfilling operation was to be carried out “sequentially”, although the report says that the use of the word “sequentially” in the method statement is ambiguous and does not clearly define the process to be followed.

It says that the method statement referred to backfilling around the arches, but not across the full width of the tunnel, as the specification required.

The report goes on to explain that WYG requested the arch units be monitored for deflections but that engineers on site were initially unaware of this. When Jackson did start monitoring the units for deflections, the results were ignored and the site management team failed to act on “very large deflections” of more than 150mm.

“Thus, had the works been completed without collapse, large areas of the structure would have been in a condition not foreseen by its designers and hence well outside its design parameters,” the report states.

“Nobody on site was aware of this situation at the time it occurred.”

In the weeks leading up to the collapse, Jackson engineers inspected the intrados levels at the east and west portals. It was found that the west portal was 125mm lower than its design position. The results were passed on but no actions were taken.

Similarly, the crown at the east end was found to be 147mm below those shown in WYG’s drawings, but again this was not acted upon. Two days before the collapse, the levels were measured again and found to be even lower, but nobody is sure what was done with this information, according to the HSE.

On the evening of 30 June 2005, part of the tunnel collapsed, with the crown caving in. Twenty-nine arch sections, each weighing 22t and thousands of tonnes of backfill fell onto the track and blocked it. There were no trains on the affected section of the line at the time, but two were approaching it and one had to apply its emergency brakes. The railway was closed for seven weeks, causing massive disruption.

In conclusion, the HSE report quotes a 2005 report into the incident that was signed off by Jackson and WYG: “Network Rail’s view on the cause of the collapse was inadequate fill material around the arch haunches compared to the fill directly over the crown. In [its] opinion this was a classic mode of failure, with the arch deflecting under the weight of the backfill over the crown with insufficient fill to the sides to resist the forces.

“Consequently, plastic hinges formed at the haunches and this allowed the crown pin to snap through or dislocate and resulted in collapse.”

Costain was appointed by Tesco in 2006 to construct the tunnel and the supermarket. A more cautious approach was taken to the tunnel using continuous precast arch segments. It was completed in 2010.

- The findings of HSE report are discussed in the most recent episode of the “Rail Natter” podcast and the report is available to view on the Railways Archive: https://tinyurl.com/TescoTunnel