Future of Water | Auckland Central Interceptor

Tackling overflows

New Zealand’s largest ever wastewater infrastructure project is underway. It will reduce combined sewer overflows and water pollution. Sotiris Kanaris reports.

In September, a tunnel boring machine (TBM) for the 14.7km Central Interceptor tunnel in Auckland, New Zealand broke through into a 69m deep shaft at May Road. It had completed the first of the tunnel’s two drives.

The tunnel is part of local water and wastewater provider Watercare’s NZ$1.2bn (£590M) Central Interceptor project, the largest wastewater infrastructure project in New Zealand’s history.

The project’s aim is to reduce combined sewer overflows and consequent pollution resulting from the existing network’s inability to cope with heavy rain and wastewater volumes generated by Auckland’s growing population – which has reached 1.7M people.

The project’s aim is to reduce combined sewer overflows and consequent pollution resulting from the existing network’s inability to cope with heavy rain and wastewater volumes generated by Auckland’s growing population – which has reached 1.7M people.

Watercare expects the Central Interceptor to reduce the annual overflow volume in the city’s Waitemata and Manukau harbours by as much as 80%.

Central Auckland’s original sewer network was built in the early 1900s and then extended in the 1950s and 1960s. In this part of the city there are three interceptors – the 18.2km long Eastern Interceptor, the 13.6km long Orakei Main Sewer and the 19.5km Western Interceptor – which are connected to form an almost circular system.

These interceptors enable wastewater to flow clockwise until it reaches the Mangere Wastewater Treatment Plant (WWTP) in the southern suburbs. Here, most of the city’s wastewater is treated at an average volume of 300,000m3 per day.

Wastewater and stormwater flow into a combined network of pipes which are linked to the interceptors. This combined sewer system is often overwhelmed during wet weather, resulting in overflows.

The need for new infrastructure to tackle the issue was identified in the 1990s. Studies carried out between 2005 and 2008 recommended the construction of a central interceptor providing a direct connection between the Orakei Main interceptor – built in 1911 – in the north part of Central Auckland and the Mangere WWTP.

Watercare executive programme director Shayne Cunis describes this as the “spine” bisecting the existing network.

The concept design for the central interceptor was completed in 2011, with the final planning consent granted in 2015. The detailed design was carried out by Jacobs, Delve Underground and Aecom and completed in early 2018.

A year later, Watercare appointed Ghella-Abergeldie Joint Venture (GAJV) as the main contractor. GAJV is also responsible for the design of certain elements such as the main tunnel lining, 14 permanent shafts and an air treatment facility, with Arup awarded the contract for these designs.

Cunis says the project’s unprecedented scale and value caused concern among Watercare board members, but the need for this infrastructure led to the necessary funds being unlocked.

“A lot of utility companies don’t want large projects on their balance sheet because they often go wrong. We were used to delivering NZ$10M NZ$15M projects and here comes one costing over a billion dollars. In the past the cost of things going wrong might have been hundreds of thousands of dollars, not hundreds of millions. Everyone was quite nervous, understandably,” he explains.

Among the actions taken to reassure the board that costs would be kept under control were the investment in risk management resources with experience in major projects. There were also qualitative risk assessments to support risk funding within the business case; and change management processes.

KEY FACTS

£590MCost of Central Interceptor project

14.7kmLength of main tunnel

55,000Number of tunnel lining segments

PROJECT SCOPE

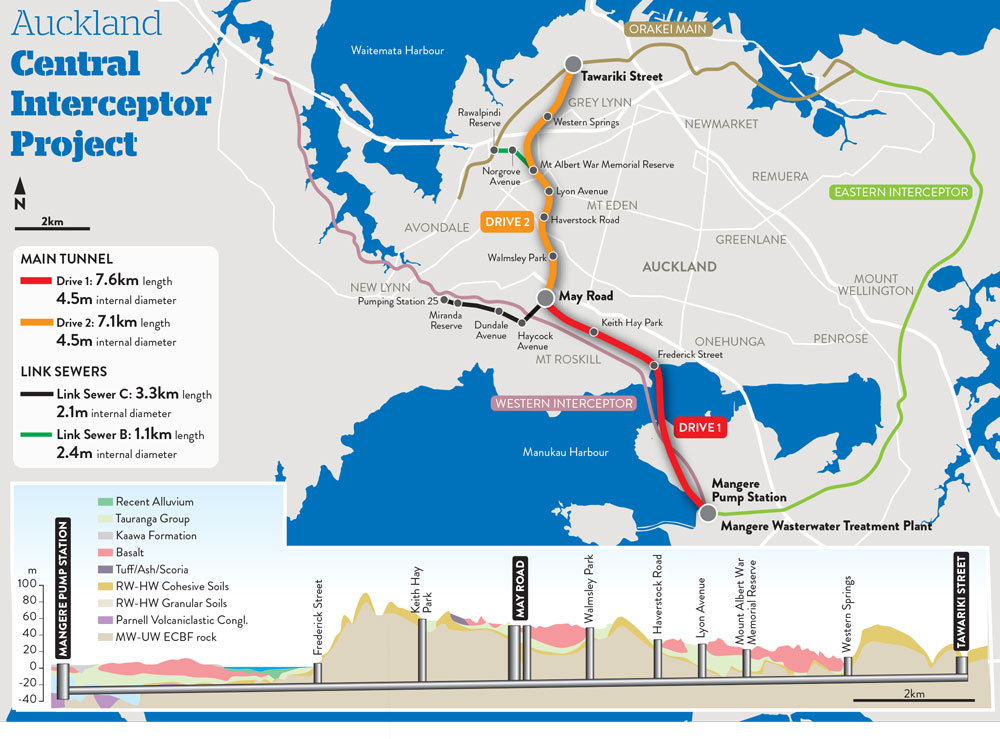

The Central Interceptor project involves the construction of the main tunnel, two link sewers connecting to the main tunnel and a new pumping station at the Mangere WWTP.

The 14.7km main tunnel will run from north to south from Tawariki Street in the city centre to the new pumping station. It will have an internal diameter of 4.5m and its depth will range from 15m to 110m.

The tunnel will have the capacity to store 226,000m3 of wastewater, allowing Watercare to control the flow rate into the treatment plant for the first time.

“It gives us more flexibility. This is really a game changer for how we run the wastewater system,” says Cunis.

“This is really a game changer for how we run the wastewater system

More than 55,000 precast concrete tunnel lining segments will be installed, six for each tunnel ring.

The main tunnel will be protected from sewer corrosion by a mechanically anchored polyethylene corrosion protection lining (CPL) with a minimum thickness of 3mm, covering the full 360° of the tunnel intrados.

GAJV opted to cast the CPL directly onto the precast segments, building on experience with a similar system used for the Inner Doha Re-sewerage Implementation Scheme in Qatar.

Two new link sewers will feed into the Central Interceptor tunnel. The 3.3km long, 2.1m diameter Link Sewer C will run west from a junction with the interceptor to Pumping Station 25. A shorter 1.1km, 2.4m diameter tunnel will branch off to the west of the main interceptor, 3.7km upstream.

The new pumping station, at the northern end of the Mangere WWTP, will pump wastewater from the tunnel to the plant at a rate up to 7.2m3/s. It is an essential component of the project, as it will help Watercare provide a stable flow of wastewater to the treatment plant.

A total of 17 shafts with diameters ranging from 3m to 10.8m, will be constructed across 16 sites along the main tunnel and link sewers.

GROUND CONDITIONS

A series of ground investigations was carried out before the main tunnel route was finalised, as certain ground conditions had to be avoided.

“The Auckland area has 53 volcanic cones and explosion craters, many of which are associated with basalt flows. The early design of the project went to some lengths to identify and avoid tunnelling through volcanic materials,” explains Watercare tunnel shafts delivery manager Jon Sickling.

He says volcanic materials could damage an earth pressure balance (EPB) TBM’s cutterhead. EPB machines are the preferred TBM type because of their proven track record in Auckland’s rock conditions.

An earth pressure balance TBM was selected for the construction of the 14.7km main tunnel

An earth pressure balance TBM was selected for the construction of the 14.7km main tunnel

The geology under Auckland is typically East Coast Bays Formation (ECBF), which comprises an alternating sedimentary sequence of weak sandstones and siltstones mudstones.

GAJV project director Francesco Saibene characterises the ECBF spoil as “very sticky”. The JV had heard of challenges with spoil management during the Waterview Connection twin road tunnel construction in Central Auckland – completed in 2017. Particular attention was paid to soil conditioning to avoid encountering the same challenges.

Apart from ECBF, the ground investigations revealed areas along the route where the ground comprises Kaawa Formation and Tauranga Group, which are even more challenging to excavate.

Kaawa Formation typically comprises dense sands, while the Tauranga Group consists of soft silts, clays and pumiceous deposits.

There are also expectations that some pockets of Parnell Grit – a collection of thick, coarse volcaniclastic beds – will be found. Parnell Grit has a higher uniaxial compressive strength than ECBF.

CONSTRUCTION PROGRESS

A 190m long Herrenknecht TBM with a 5.45m cut diameter was selected to bore the main tunnel.

GAJV split the main tunnel construction into two TBM drives to be executed by the same machine. The first drive covers a distance of 7.6km from the Mangere pump station to May Road, the junction with Link Sewer C, and the second stretches 7.1km from the May Road breakthrough shaft to Tawariki Street.

Saibene says the most challenging parts of the job were in the recently-completed first drive. Kaawa Formation and Tauranga Group sediments were found close to the Mangere launch shaft, while there were mixed ground conditions with some Parnell Grit and higher-than-expected water levels near the May Road shaft.

The first drive also included a 1.5km section in ECBF under Manukau Harbour, with the TBM working with 15m cover to the seabed.

“The early design of the project went to some lengths to identify and avoid tunnelling through volcanic materials“It was the first harbour crossing with a TBM done in New Zealand, so there were no records to rely on. There was concern that if something went wrong we could have had a sinkhole in the harbour which would have flooded the tunnel. In the end the ground conditions were okay and we managed to control the pressure in the chamber,” says Saibene.

An EPB micro-tunnelling machine was used to bore Link Sewer C which started in June 2021 and was completed this March, four weeks ahead of schedule.

The longest drive length was a curved 1,9km drive, which was a national record for this type of micro-tunnelling. The same TBM is already making progress on Link Sewer B, which is expected to be completed in May 2024.

Work is progressing on the Mangere Pump Station while inflow pipes and six pumps are being installed. Watercare aims to bring the pump station online by the end of next year.

The first section of the main tunnel and both link sewers are due for commissioning in mid-2024. This will relieve the Western Interceptor and allow Watercare’s operations team to carry out essential maintenance.

More than 600 people are currently working on the project across all 16 sites. Saibene says the original plan was not for the work to be executed simultaneously, but the impact of Covid-19 lockdowns, global shipping delays and extreme weather events meant the work sequence had to be altered so that the project can be completed in 2026 on schedule.

Cunis says the Central Interceptor will help Watercare meet its target of having no more than two overflows per point on its network by 2030.