Future of Water | Gross Reservoir

Capacity boost

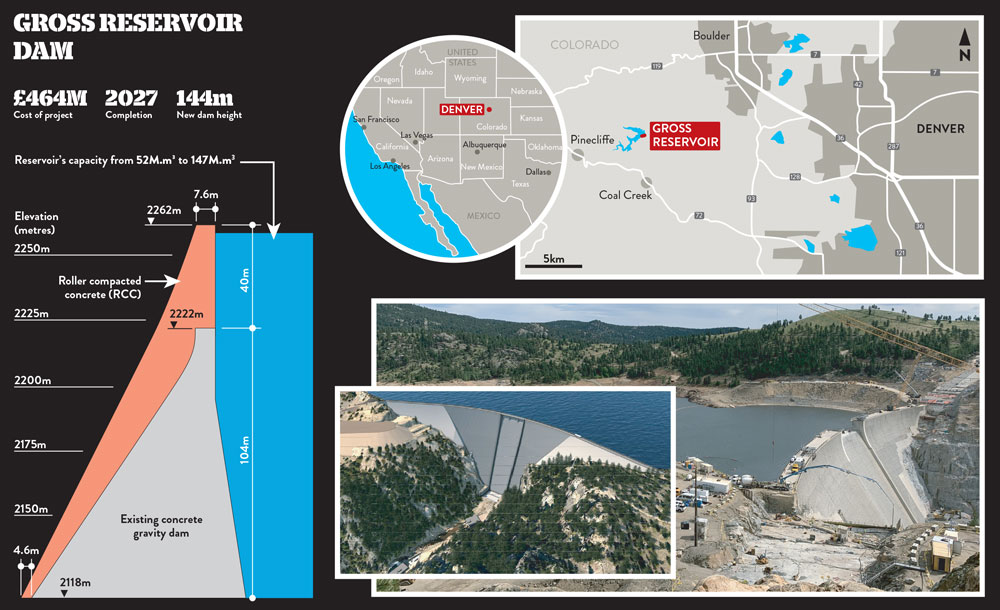

A project to boost the resilience of Denver’s water supply will triple the capacity of Gross Reservoir by raising the crest of its dam. Helena Russell reports.

Twenty years since Denver, Colorado almost ran out of water, a major scheme to address the vulnerability of its water supply is taking shape in the region’s north basin, north west of the city.

The $565M (£464M) construction project will add 40m to the height of Gross Reservoir dam, which currently stands at 104m.

Raising the dam’s height will boost the reservoir’s capacity from 52M.m3 to 147M.m3, making it Denver Water’s second largest. After a severe drought in 2003, a threatened water shortage was prevented by snowfall. But as Denver Water project manager Jeff Martin explains, the crisis underlined the issue of resilience and prompted the utility to take action.

“We needed to be more nimble and to address the issue of climate uncertainty and more frequent extreme weather events,” Martin says.

Finding the right solution has taken time; a previous scheme proposing a new reservoir in the south basin failed to meet the robust assessment criteria set out in the United States’ National Environmental Policy Act.

Denver Water focused instead on increasing the capacity of its existing facilities, with the Gross Reservoir expansion identified as having the least environmental impact.

The designers of the 1950s-era concrete gravity dam future-proofed it, anticipating that it would be raised using the same construction methods, Martin reveals. “But concrete dam technology has changed, moving from conventional construction to roller compacted concrete (RCC), which can be placed faster and with better control of the heat of hydration.”

KEY FACTS

147M.m3Capacity of Gross Reservoir after dam height is raised

90%Share of Denver Water’s water supply originating from the southern basin

RECONFIGURATION

RCC will be built up in layers across the entire front face of the existing dam, all the way from the base to the crest and 40m higher. The new design also reconfigures the structure’s geometry so that when the project is complete, it will act as an arch dam rather than a gravity dam.

This radical intervention takes advantage of the fact that the existing gravity structure follows a curved form in plan.

According to design consultant Stantec’s global dams practice leader Mike Rogers, an arch dam is more robust, with additional redundancy. It has a narrower base and requires less foundation excavation, and on this project he estimates the arch design reduces the amount of concrete needed to raise the dam by 20%.

Nevertheless, the scale will be significant. “We believe this will be the largest raise of a dam using roller compacted concrete in the world,” Rogers says.

The current record holder is the San Vicente Dam in San Diego, California to which 35.6m was added.

In Denver the dam was originally designed to accommodate a height increase of 36m, 4m lower than the current scheme. “However we have had to design abutments in order to go higher, since the existing dam already reaches the top of the valley,” Rogers says.

One of the biggest challenges was the uncontrolled spillway that will be retained in the middle of the structure.

A key feature of RCC construction is that the concrete is laid in 300mm lifts that are stepped in on every fourth raise, changing the smooth face of the existing spillway to one with 1.2m steps.

Physical modelling of the new structure was required to analyse energy dissipation to minimise any risk of undermining the foundations.

CONSTRUCTION PROCESS

Joint venture contractor Kiewit Barnard kicked off construction in 2022 and as deputy project manager Todd Orbus explains, the work is divided into two main phases – preparation of the existing structure and construction of the new one.

The RCC layer must form a composite bond with the existing structure to eliminate stress concentrations. Vertical faces are laid back to 45°, with hydro demolition used to remove surface material that has deteriorated over 70 years of freeze-thaw cycles. Conventional airentrained concrete will be placed on the RCC’s external face to resist future cycles.

“Our goal is to start the dam raise on 1 May 2024,” Orbus says.

“At the start we had to do a lot of site development – we are in a remote location, at an elevation of 2,225m, so there are challenges with logistics, weather and seasonality.

“A million cubic yards [765,000m3] of earthworks was necessary just to improve access and create flat spaces for equipment.”

“We needed to be more nimble and to address the issue of climate uncertainty

Using RCC not only requires different means and methods of placement, it poses specific challenges for construction of an arch structure.

Hence Kiewit Barnard carried out a full-scale trial at a test site, involving placement of more than 3,800m3 of RCC over an area 15m wide, 76m long and 6m deep, which was completed in early October.

Most of the trial focused on the operation of the batching plant, the mix design and delivery, and establishing the conditions necessary to ensure the concrete is just 10°C at the point of placement.

Rather than being delivered through a concrete pump, the RCC mix – which is drier than conventional concrete – is brought in by truck, spread by bulldozer and compacted by rollers.

Temperature control and setting time are crucial, not just to minimise cracking, but also to manage the joints between layers.

Mixes will be adjusted as the dam rises through the four-year build, gradually reducing the extent to which strength gain is retarded. The aim is to ensure that all levels of the new structure reach full strength at the same time.

Other challenges come from the fact that production rates are so variable. “At the bottom of the dam the RCC layers are narrow and short, so rates are low; the thickest and widest part is at the top of the crest where production rates will be higher,” Orbus says.

Above the existing crest, formwork will be needed on the upstream and downstream faces of the dam, increasing the workforce required by about 30%, he predicts.

Increasing the height of the dam will take place over two consecutive years in seasons that run between May and November, dictated by the temperature differentials at the site, where overnight frosts usually start in October. Forty percent of the RCC volume is expected to be placed in the first phase and the rest in the second, with completion of the entire project scheduled for 2027.